Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

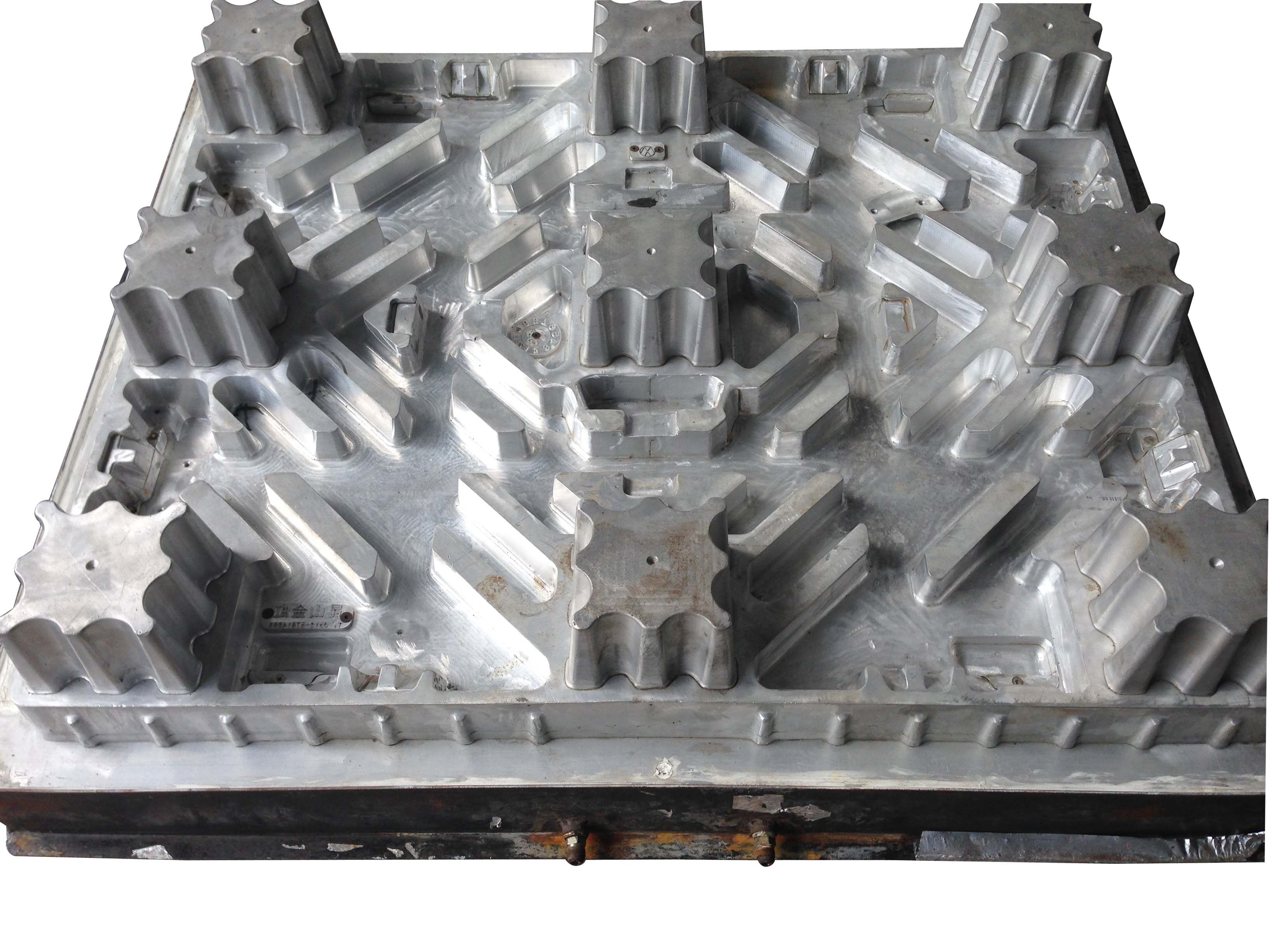

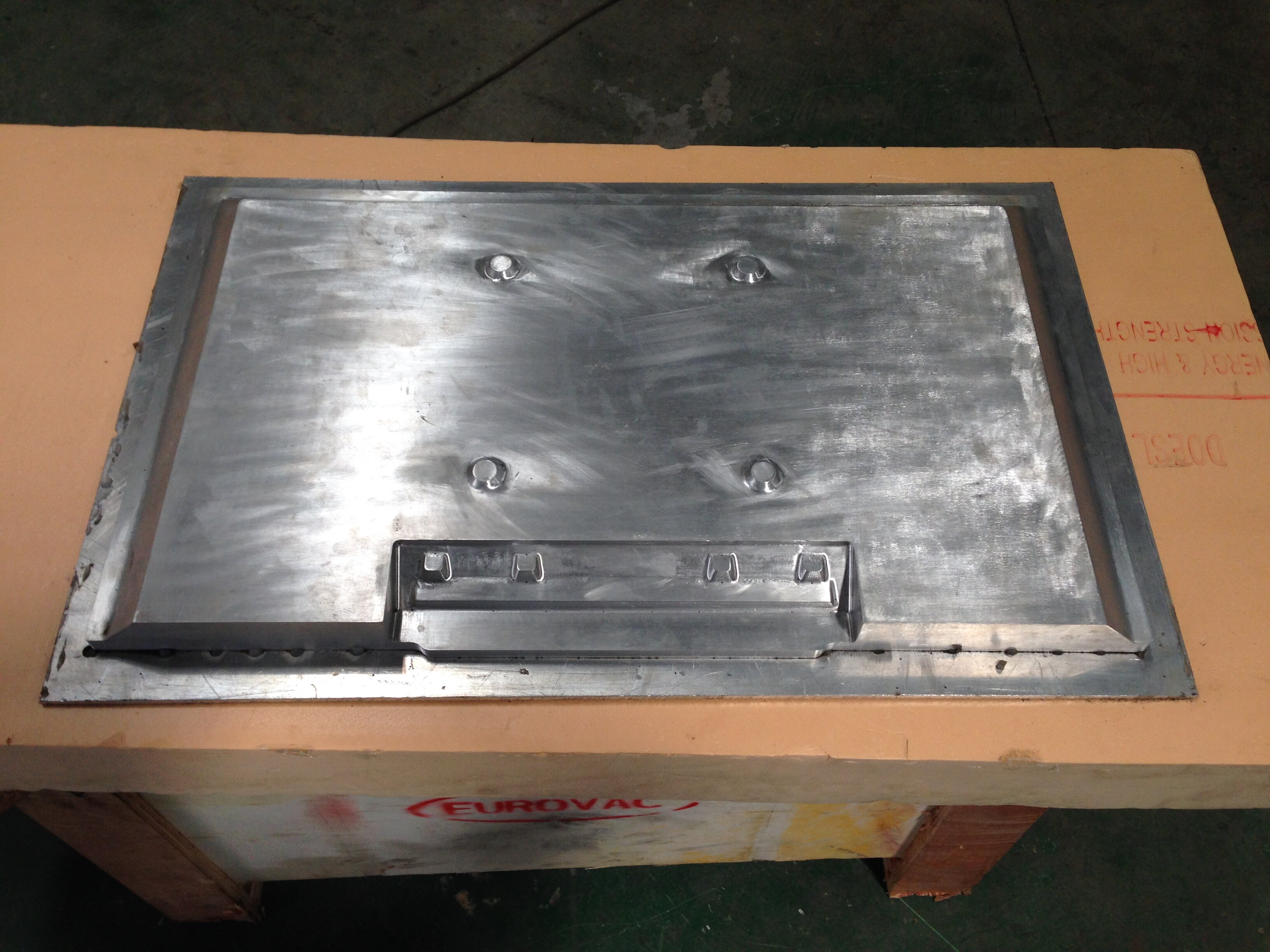

The vacuum blister mold is durable and long-lasting, the time to manufacture is short, so you can receive it as quick as possible, but if the mould you showed us is too complicated, it may need to spend more time on making. The molds have lower tooling costs than traditional molding methods, making them cost-effective for small to medium production runs. Besides, it can make the products produced with a smooth and uniform surface finish, reducing the need for additional finishing processes.

Short Lead Time:

Vacuum blister mold can produce parts at a faster rate than traditional molding methods, reducing lead times and increasing productivity. And it has a simpler setup process than traditional molding methods, reducing setup time. Otherwise, it can be used to produce a wide range of parts, including complex shapes and sizes, making them suitable for a variety of applications.

Lower Cost:

The vacuum blister mold can help you to use less material than traditional molding methods, reducing material waste and lowering costs. What’s more, it can produce parts at a faster rate than traditional molding methods, reducing labor costs and increasing productivity.

Customized Design:

It can be customized with different kind of shapes and sizes, if you need different material, you can also contact with us. We can support customized service from real factory, if you want to get quick quote, you can leave message to us.

The Maintenance of the Vacuum Blister Mold?

1. The thimble and guide post of the injection mold should be kept lubricated (the most suitable lubricant should be selected), and the thimble and guide post should be regularly checked for deformation and surface damage. Once you found them, they should be replaced in time.

2. Pay attention to the surface maintenance of the injection mold, which directly affects the surface quality of the product. The focus is to prevent corrosion. Therefore, it is particularly important to choose a suitable and professional anti-rust oil.

3. Each pair of injection molds should be recorded, with the detailed records and statistics of its use, care (lubrication, cleaning, anti-rust) and damage, so that it can be found which parts and components are damaged and the degree of wear, so as to provide information and problem-solving information.

4. Each part on the injection mold should be measured. Make comparisons and make records so that problems can be discovered in due course and countermeasures can be taken.